The vulnerability of pharmaceutical supply chains to disruptions especially applies to the Netherlands, where 5 out of 13 million medicine users were affected by medicine shortages in 2023. This is largely attributed to price-focused regulations and procurement practices that pressure manufacturers' margins, resulting in market exits and insufficient investment in supply chain resilience.

Win-win-win outcomes

To address this, the Dutch government is implementing two key interventions: mandating minimum stock levels (creating an “iron stock” or “ijzeren voorraad”) and revising maximum price policies. These measures aim to enhance supply resilience and the earnings capacity of supply chain actors (to prevent them from exiting the market) but can strongly increase holding costs and prices, and thereby decrease drug affordability.

The key to improving supply resilience and supply chain actors’ earnings capacity without strongly decreasing affordability lies in tailoring these policies. Different medicines vary in price, margin, revenue, disruption risk, and supplier alternatives, making a one-size-fits-all policy ineffective. Tailored policies – specifying different minimum stock levels and different approaches for determining maximum prices for different categories of medicines – even have the potential to create win-win-win outcomes: better supply resilience, improved affordability (by saving costs of shortages and avoiding unnecessary stocks) and fewer market exits (by decreasing holding costs and increasing earnings potential for medicines for which this risk is high).

Maximise tailored policy’s effectiveness

The project aims to develop differentiated policies for maximum prices and minimum stock levels that are simple enough for practical implementation. The research team will take a step-by-step approach, starting with stakeholder interviews to understand the feasibility, costs, and benefits of different levels of policy tailoring. Then they will use a staggered difference-in-difference model to quantify how the policies affect resilience, affordability, and earnings capacity, using data on medicines and shortages in the Netherlands. The data and findings will be used to develop a policy impact model that estimates the effects of minimum stock levels and maximum prices on supply resilience, affordability, and market exits.

The researchers will use those insights and the policy impact model to solve the problem of optimising policy tailoring. The goal is to maximise the tailored policy’s effectiveness while limiting the policy’s level of complexity. Finally, the team will evaluate tailored policies in terms of supply resilience, affordability, and earnings capacity and develop an Excel-based plug-and-play tool which stakeholders can use to evaluate differentiated policies.

Reduce costs and shortages

Ultimately, the project will suggest specific tailored policies for minimum stock levels and maximum prices, but also propose a methodology and blueprint that can be used to tailor other policies affecting pharmaceutical supply chains, such as those on failure-to-supply penalties, tendering (preferentiebeleid), and insurance coverage limits (GVS).

In 2023, the pharmacy supply chains serving pharmacies in the Netherlands alone (excluding hospitals) generated €5.4 billion. The researchers expect that smart tailoring can reduce holding costs for the industry and shortages by 20 per cent, and the likelihood of market exits among low-revenue articles by at least 50 per cent. Dissemination will not only focus on the Dutch pharmaceutical sector, but also on other countries (vertical scaling) and other supply chains affected by government policies (horizontal scaling) – to maximise the project’s impact.

The research team

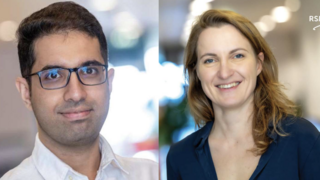

The three-year collaborative project will be co-ordinated by Dr Harwin de Vries.

Dr Harwin de Vries is an associate professor in RSM’s Technology and Operations Management department. His research focuses on health and humanitarian logistics. Harwin has collaborated closely with more than 20 humanitarian/health organisations, studying how key decisions in health/humanitarian supply chains affect patients or beneficiaries and how they could be improved. Harwin won several prizes with his research, and attracted several research grants, including the 2022 NWO VENI grant. He also serves on the board of the POMS College of Humanitarian Operations & Crisis Management. Harwin holds a PhD degree in operations research from the Erasmus University Rotterdam.

Dr Stef Lemmens is an assistant professor in RSM’s Technology and Operations Management department. His research focuses on designing and modelling sustainable supply chains, more specifically humanitarian and closed-loop supply chains. He relies on queueing networks, mixed integer programming and dynamic programming to analyse and improve their performance. His work is practice-based and in collaboration with companies in the consumer electronics and biopharmaceutical industry. Before joining RSM, Stef obtained his PhD in applied economics at KU Leuven (Belgium) and worked as a postdoctoral researcher at INSEAD’s Technology and Operations Management (France).