Discovery speaks to Adriana Domínguez – guest speaker on the RSM EMBA programme and Executive President of Spanish fashion firm Adolfo Domínguez – about the logistical challenges and design challenges that the company encountered when the Covid pandemic hit in 2020.

On 28 February 2020, things were looking up at my company, Adolfo Domínguez, a multinational fashion company based in Ourense, Spain. We had just gotten through a difficult, wrenching three-year turnaround. For the first time since the financial crisis, we had broken even. Then two weeks later, the pandemic began.

It was an impossible situation – even psychologically, for the whole team and for myself – coming as it did right after all those tough years. I kept saying, Oh no, this is not happening! But it was.

What helped me get a grip was a book called Antifragile: Things that gain from disorder by Nassim Nicholas Taleb. He helped me twist my mindset around and realise that what we were going through was not some drama that is just happening to us, but that sometimes, the world changes very quickly, and you have to adapt. Instead of just bracing yourself for the next oncoming disaster, you have to change your perspective and see how you can turn these circumstances into an opportunity.

The company was founded in the early 1970s when her father, fashion designer Adolfo Domínguez took over his father's boutique in Ourense in Spain. That first store grew into a chain with 400 outlets across Spain and internationally, and the company has an annual turnover of around €182 million.

One of the few advantages of a crisis is that you have much more creative freedom. You can do whatever you want and try whatever you want because nothing else is working.

Figuring out how to use that freedom, however, took time. Eventually, we decided to focus on two big opportunities: to accelerate our sustainability plan and to automate.

Six months before, we had asked our Chinese production partners if they could work with us to become more sustainable, but we ran into a lot of resistance. Many of our suppliers weren’t willing to start doing something that would be more difficult, more expensive, and new – particularly for a client that was becoming less important to their business than their growing base of domestic clients.

But Covid changed that equation. Our Chinese suppliers’ factories were shut down and transportation costs quadrupled. Suddenly, production closer to home became more competitive and affordable. We focused on Portugal, and from one season to the next we increased from 0.5 per cent to 30 per cent our nearshore production in factories within a radius of 200 kilometres from the factory, and with suppliers who were certified for sustainability.

Nearshoring had several advantages that were now compelling in this new era. We didn’t have to produce so far in advance or so much. We could also drive our sustainability goals without driving up our costs. Having our suppliers next door also made management easier. All in all, it worked so well that we expected to end 2022 with 50 per cent of our products coming from nearshore suppliers.

The pandemic also helped us accelerate automation. We are not a start-up – my father founded the company 46 years ago. Our design team includes people from several generations: from young people who come out of design schools in their twenties really knowing how to use the latest digital tools, to experienced designers in their fifties who are often less comfortable with that way of designing, but are valuable to the company.

I felt some resistance to the new system from the older designers. We gave them the education that they needed to ramp up, but in Spanish you say they also need to have la voluntad – the will. Skill you can fix, but the will has to be there too.

The pandemic accelerated this acceptance because we had no choice. For example, when we installed something called Product Lifecycle Management – a digital, cloud-based system for sharing our designs with our suppliers – we had to get all the designers, young and older, to change the way they worked.

I felt some resistance to the new system from the older designers. We gave them the education that they needed to ramp up, but in Spanish you say they also need to have la voluntad – the will. Skill you can fix, but the will has to be there too.

The pandemic accelerated this acceptance because we had no choice. For example, when we installed something called Product Lifecycle Management – a digital, cloud-based system for sharing our designs with our suppliers – we had to get all the designers, young and older, to change the way they worked.

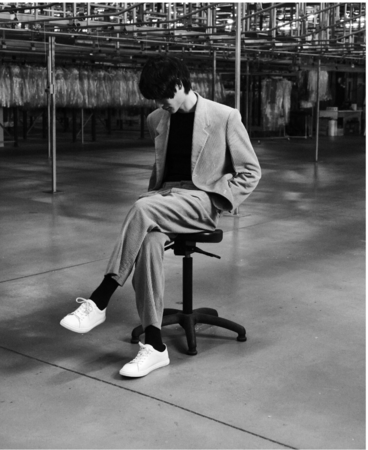

The pandemic may be over but our transformation isn’t. These days, I’m focusing on what our brand means as things continue to change. One result of Covid is that people are dressing more informally, so we are producing more informal collections.

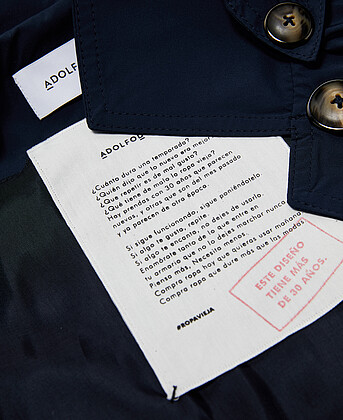

Sustainability is a core value, by which we mean not just trying to make clothes in less environmentally destructive ways, but making clothes that don’t wear out quickly. Clothes used to be made to last 10 or 20 years, and we want to make things like that again; garments that are high quality and have a timeless style, so they are special now and will still look fashionable 20 years from now.

One way we are trying to get people to think of clothing as a long-term investment is by taking out advertisements in Vogue with models dressed in clothes we made 20 years ago. We are trying to get people to think more along the lines of a lovely old-school saying people used to tell family members in Spain 80 years ago, “Make sure you buy something expensive. Remember that we’re poor.”

My point here is not that we’re a hugely expensive brand but that we should encourage people to buy products that will hold their value.

Whatever you dress in, it’s your second skin. It says quite a lot about you. Not everyone should look the same. We should all try and decide on our clothes as being a symbol to define who we are, and for us to be comfortable with that image. Even now, despite everything, we think that beauty still has a place in the world.

Adriana Domínguez is Executive President of Adolfo Domínguez.

Science Communication and Media Officer

Rotterdam School of Management, Erasmus University (RSM) is one of Europe’s top-ranked business schools. RSM provides ground-breaking research and education furthering excellence in all aspects of management and is based in the international port city of Rotterdam – a vital nexus of business, logistics and trade. RSM’s primary focus is on developing business leaders with international careers who can become a force for positive change by carrying their innovative mindset into a sustainable future. Our first-class range of bachelor, master, MBA, PhD and executive programmes encourage them to become to become critical, creative, caring and collaborative thinkers and doers.